The concept of carbon capture and storage usually involves sending CO2 from power plants deep underground. But what if there were productive uses for the greenhouse gas that would lock it away permanently without having to bury it?

That’s been the mission of several teams working at the Wyoming Integrated Test Center (ITC), a production-scale research facility on the grounds of Basin Electric Power Cooperative’s Dry Fork Station in Gillette, Wyoming.

CarbonBuilt, a team of researchers affiliated with UCLA, produced 10,000 standard cinderblocks at the site last year. Each one was infused with about 12 ounces of carbon dioxide in a mineralization or carbonation process that helped the team win a share of the NRG-COSIA Carbon XPRIZE, a $20 million global competition to spur research into beneficial CO2 use.

“Our process infuses CO2 into concrete masonry or precast concrete during the curing phase, which occurs in the factory,” says Gaurav N. Sant, who led the CarbonBuilt team, adding that cinderblocks and precast concrete represent about 30% of worldwide concrete demand. “The unit economics of products made with our technology are better than traditional concrete.”

The work at the ITC is part of a global effort to dramatically reduce the environmental impact of power generation. Some see retaining the viability of coal and natural gas as critical to meeting demand for electricity in the coming years, as increases in the use of electric vehicles and other power-hungry systems drive up global electricity use.

“No question, we’re going to need these dispatchable thermal power sources to meet demand and grid operations, at least for the foreseeable future,” says Emma Stewart, NRECA’s chief scientist. “Developing technologies that not only keep fossil fuel emissions out of the atmosphere but can capture and use them in economically sustainable ways completely changes the game in terms of how we meet the world’s energy needs well into the future.”

[image-caption title="The%20Wyoming%20Integrated%20Test%20Center%20produced%20about%2010%2C000%20cinderblocks%20last%20year%2C%20each%20infused%20with%2012%20ounces%20of%20carbon%20dioxide." description="%20" image="%2Fremagazine%2Farticles%2FPublishingImages%2FITC-cinderblock-square.jpg" width="600" /]

Early support

Electric cooperatives were among the earliest supporters of the ITC. Dry Fork Station is located in Wyoming’s Powder River Basin, and Powder River Energy CEO Michael Easley worked for years to build interest in a permanent carbon research presence in the region.

“We were working with then-Gov. Matt Mead and considering what would happen if, due to environmental pressures, coal fell out of favor because of CO2 and was no longer available for use as a [electric] generation fuel,” recalls Easley, who once served as chair of the Wyoming Infrastructure Authority. “Our larger strategy was to harness proven research to build a CO2 asset network that really looked at ways to effectively reduce atmospheric CO2 and create economic opportunities around that while reducing the waste stream for our industry and others.”

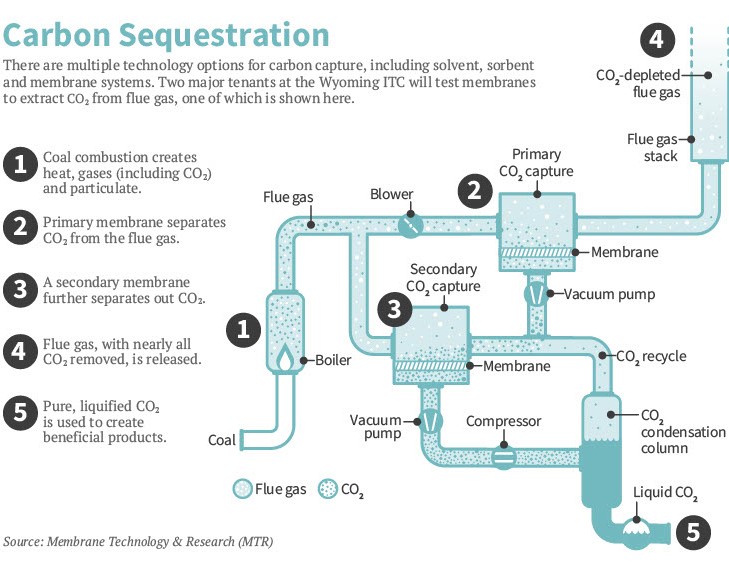

Hosting the research and proving its commercial value were ideal roles for the ITC. The facility is located next to Dry Fork Station, a 405-megawatt coal power plant commissioned in 2011. A pipeline connected to the plant’s exhaust system delivers flue gas containing CO2 for use by institutional and industrial tenants conducting production-scale research.

“We have six small test bays that can host projects of about a half a megawatt-equivalent each,” says Jason Begger, the ITC’s managing director. “They’re largely built offsite, brought in, set up within a week to run for several months and taken away.”

Begger says a larger test bay will be used for the $64 million Membrane Technology & Research initiative, a carbon capture project now being designed with help from the U.S. Department of Energy. The project is expected to utilize flue gases representing 10 MW of generation during Phase III testing.

“At this scale, we will be able to demonstrate carbon capture technology at a sufficient level to demonstrate to utilities the next step can be a commercial version,” he says.

As the top coal-producing state, Wyoming’s support of research preserving the value of coal for energy production and other purposes has been an economic priority, and the ITC was created to help ensure that it remains a viable resource.

“This is exactly the type of research that was envisioned when the ITC was developed, and Wyoming will continue to support these efforts,” says Wyoming Gov. Mark Gordon. “This is also an example of technology that, if commercially successful, can be exported for carbon capture projects at home or abroad.”

‘Important results’

‘Important results’

At the root of the effort is the time-tested conviction that no conundrum is insurmountable when met with co-op problem-solving and new technology.

“Technology advancement drives economic development and cleaner energy,” says Duane Highley, CEO of Tri-State Generation and Transmission Association. The Denver-based G&T provided $5 million in matching funds that led to the development of the ITC and, despite a commitment to phase out coal generation, remains interested in research conducted at the facility.

“With Wyoming’s leadership, the Integrated Test Center’s hosting of the Carbon XPRIZE enabled the advancement of novel technology solutions to carbon challenges. As more innovators come to Wyoming to evaluate technologies, the work of the ITC will continue to deliver important results,” Highley says.

Size and volume, unrivaled by smaller research facilities, reinforce the ITC’s value. Its connection to an operating power plant shows that carbon enterprises can be run safely without affecting the plant.

“Laboratories cannot mimic the real-world conditions of a functioning coal-based power plant,” says Chris Baumgartner, Basin Electric Power Cooperative’s senior vice president of member services and administration. “Hosting the ITC at Dry Fork Station … alleviates typical concerns over being able to transfer technology from a lab to a plant.”

Changing dynamics impacting the electric industry and the challenges represented by shifting global economic interests and climate concerns continue to drive interest in improving the viability of coal.

“We recognize that an all-of-the-above strategy that includes coal requires managing our carbon footprint, so we facilitate research that can make that possible,” says Baumgartner, adding that coal plants typically maintain abundant supplies of coal, minimizing their risks of supply volatility. “Research is important to preserve baseload generation to ensure reliability, which is why Basin Electric is involved with several projects researching carbon capture and technology.”

All agree the industry’s CO2 challenges are complex and will require innovation.

“What’s happening at the ITC is one part of the solution, but it is absolutely necessary if we’re going to keep all our options open,” says Jim Spiers, NRECA senior vice president for Business and Technology Strategies. “The world is watching, especially now after the XPRIZE announcement. Electric co-ops have always risen to the challenges we’ve faced. This will be no different.”